Since pricing and corrosion resistance are both equally important when deciding a grade for a particular selection. In case of Duplex and Stainless Steel 316, there is no clear winner. Metline Industries supplies high quality Duplex stainless steel 2205 rods and bars, as well as Stainless Steel 316L stainless steel bars and rods. Both grades have their special qualities, due to which they are accepted for wide range of applications across various industry verticals.

While, reading and gather information both the grades – we came across some important observations, as below:

In terms of “Corrosion Resistance” – Duplex stainless steels exhibit a high level of corrosion resistance in most environments where the standard austenitic grades are useful.However, there are some notable exceptions where they are decidedly superior. This results from their high chromium content, which is beneficial in oxidizing acids, along with sufficient molybdenum and nickel to provide resistance in mildly reducing acid environments. The relatively high chromium, molybdenum and nitrogen also give them very good resistance to chloride pitting and crevice corrosion. Their duplex structure is an advantage in potential chloride stress corrosion cracking environments. Duplex alloys are more resistant to chloride stress corrosion cracking than Types 304 and 316.

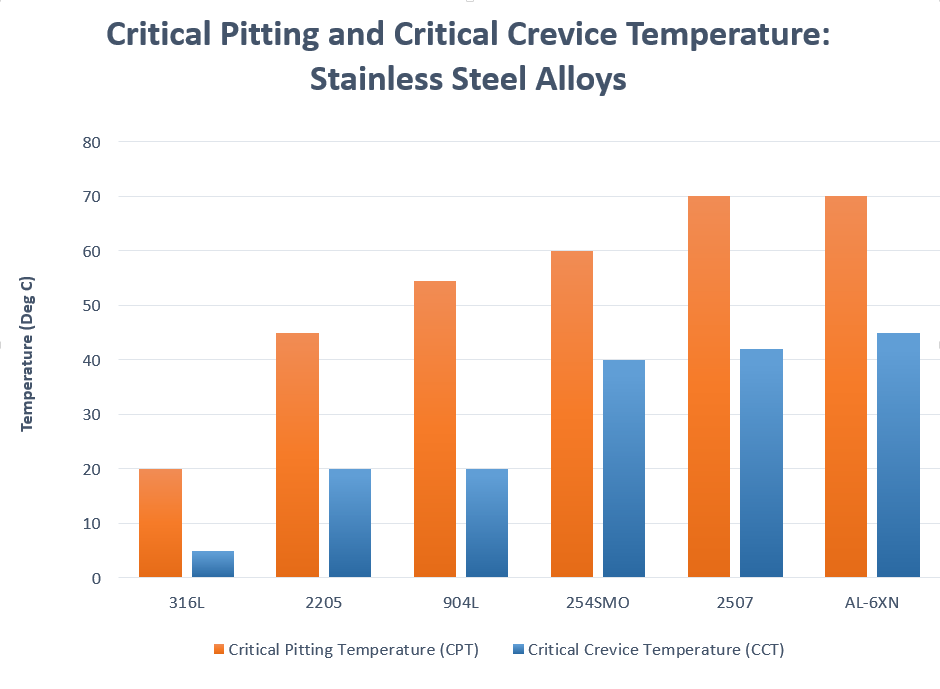

With Respect to “Pitting and Crevice Corrosion Resistance” – The high chromium, molybdenum and nitrogen contents in duplex grades provide very good resistance to chloride-induced localized corrosion in aqueous environments. All but the very lowest alloyed duplex stainless steels are far superior to Type 316 in this respect. Depending on the alloy content, some duplex grades are among the best performing stainless steels. Because they contain relatively high chromium content, duplex stainless steels provide a high level of corrosion resistance very economically. A comparison of pitting and crevice corrosion resistance for a number of stainless steels in the solution annealed condition as measured by the ASTM G 48 procedures (10% ferric chloride) is given in Figure 1. Critical temperatures for materials in the as-welded condition would be expected to be somewhat lower. Higher critical pitting ( CPT) or crevice corrosion temperatures (CCT) indicate greater resistance to the initiation of these forms of corrosion. The CPT and CCT of 2205 are well above those of Type 316. This makes 2205 a versatile material in applications where chlorides are concentrated by evaporation, as in the vapor spaces of heat exchangers or beneath insulation. The CPT of 2205 indicates that it can handle many brackish waters and de-aerated brines. It has been successfully used in seawater applications where the surface has been maintained free of deposits through high flow rates or other means. Figure 2 shows the CCT as a function of PRE number.

Metline Industries is one of the biggest steel bars and rods manufacturer and suppliers in India with more than 20 years exports and domestic sales experience. We are specialized in supplying both stainless steel duplex round bars and stainless steel 316L round bars, stainless steel angles and stainless steel flat bars with competitive price and high quality. The quality of our stainless steel bars are highly accepted in the US, UK, Saudi Arabia, Kuwait, UAE, Australia, Qatar, Bahrain, Singapore, Africa and many other countries.

Designation Various Stainless Steel Grades – Equivalents

| AISI | EN / DIN | ASTM/UNS | EN | AFNOR | Reg.TM | Forging | |

| 410S | 1. 4000 | S41008 | X6Cr13 | Z8C12 | Ferrite | ||

| 410 | 1. 4006 | S41000 | X12Cr13 | Z10C13 | A182 F410 | Martensite | |

| 430 | 1. 4016 | S43000 | X6Cr17 | Z8C17 | Ferrite | ||

| 420 | 1. 4021 | S42000 | X20Cr13 | Z20C13 | Martensite | ||

| 420 | 1. 4028 | J91153 | X30Cr13 | Z33C13 | Martensite | ||

| 1. 4162 | S32101 | LDX 2101 | Duplex | ||||

| 304 | 1. 4301 | S30400 | X5CrNi18.10 | Z6CN18.09 | A182 F304 | Austenite | |

| 304L | 1. 4306 | S30403 | X2CrNi19.11 | A182 F304L | Austenite | ||

| 304L | 1. 4307 | A182 F304L | Austenite | ||||

| 1. 4362 | S32304/S 39230 | X2CrNiN23.4 | Z3CN23.04Az | SAF 2304 | Superduplex | ||

| 316 | 1. 4401 | S31600 | X5CrNiMo17.12.2 | Z7CND17.11.02 | A182 F316 | Austenite | |

| 316L | 1. 4404 | S31603 | X2CrNiMo17.13.2 | Z3CND18.12.02 | A182 F316L | Austenite | |

| 1. 4410 | S32750 | X2CrNiMoN25.7.4 | Z3CND25.07Az | SAF 2507 | A182 F53 | Superduplex | |

| 316L | 1. 4435 | S31609 | X2CrNiMo18.14.3 | Z3CND18.14.03 | Austenite | ||

| (Mo+) | |||||||

| 316 | 1. 4436 | X5CrNiMo17.13.3 | Z6CND18.12.03 | Austenite | |||

| (Mo+) | |||||||

| 317L | 1. 4438 | S31703 | X2CrNiMo18.16.4 | Z3CND19.15.04 | A182 F317L | Austenite | |

| 1. 4462 | S31803/S32205 | X2CrNiMoN22.5.3 | Z3CND22.05Az | SAF 2205 | A182 F51 | Duplex | |

| 1. 4501 | S32760 | X2CrNiMoCuWN25.7.4 | Zeron 100 | A 182 F55 | Duplex | ||

| 409 | 1. 4512 | Ferrite | |||||

| 904L | 1. 4539 | N 08904 | X1NiCrMoCu25.20.5 | Z2NCDU25.20 | Uranus B6/2 RK 65 | 625 N08904 | Austenite |

| 321 | 1. 4541 | S32100 | X6CrNiTi18.10 | Z6CNT18.10 | Uranus 65 / SS25L | A182 F321 | Austenite |

| 630 | 1. 4542 | S17400 | X5CrNiCunB17.4 | Z7CNU17.04 | 17.4 PH | A564 630 | |

| 1. 4547 | S31254 | 254Smo | A182 F44 | Austenite | |||

| 347 | 1. 4550 | S34700 | X6CrNiTi18.10 | Z6CNNb18.10 | A182 F347 | Austenite | |

| (H) | |||||||

| 316Ti | 1. 4571 | S31635 | X6CrNiMoTi17.12.2 | Z6CNDT17.12 | A182 F316Ti | Austenite | |

| 1. 4652 | S32654 | 654Smo | Austenite | ||||

| 1. 4662 | S82441 | LDX 2404 | Duplex | ||||

| 1. 4713 | X10CrAlSi7 | Z8Ca7 | Sicromal 8 | Ferrite | |||

| 1. 4724 | X10CrAlSi13 | Z13C13 | Sicromal 9 | Ferrite | |||

| 442 | 1. 4742 | S44200 | X10CrAlSi18 | Z12CAS18 | Sicromal 10 | Ferrite | |

| 1. 4762 | X10CrAlSi24 | Z12CAS25 | Sicromal 12 | Ferrite | |||

| 1. 4818 | S30415 | 153 MA | Austenite | ||||

| 302 B | 1. 4828 | S30215/30900 | X15CrNiSi20-12 | A182 F309 | Austenite | ||

| 309 | |||||||

| 309S | 1. 4833 | S30908 | X6CrNi22.13 | Z15CN24.13 | Austenite | ||

| 1. 4835 | S30815 | X9CrNiSiNCe21-11-2 | 253 MA | Austenite | |||

| 310 | 1. 4841 | S31000/31400 | X15CrNiSi25.20 | Z15CNS25.20 | Austenite | ||

| 310S | 1. 4845 | S31008 | X12CrNi25.21 | Z8CN25.20 | A182 F310S | Austenite | |

| 321H | 1. 4878 | S32109 | X12CrNiTi18.9 | Z6CNT18.12 | Austenite | ||

| 316H | 1. 4919 | S31609 | X6CrNiMo17.13 | Z6CND17.12 | S31609 | Austenite | |

| 304H | 1. 4948 | S30409 | X6CrNi18.11 | Z6CN18.11 | S30409 | Austenite |

Leave A Comment