Product Description

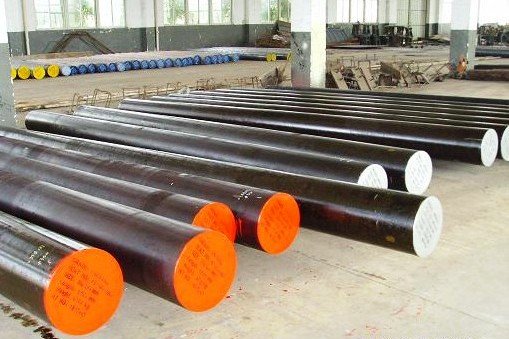

Leading Manufacturers, Suppliers of C45 Round Bars, 1045 Steel Bars , S45C Steel Bars – EN 1.0503, UNS G10450

SAE-AISI 1045 is an alloy of iron, further classified as a carbon steel. 1045 is the SAE-AISI designation for this -material. 1.0503 is the EN numeric designation. And G10450 is the UNS number. AISI 1045 is a medium carbon steel is used when greater strength and hardness is desired.

Weldability: Due to the medium-high carbon content it can be welded with some precautions.

Hardenability: It has a low hardenability in water or oil; fit for surface hardening that gives this steel grade a high hardness of the hardened shell.

Machinability: C45 Steels have good machinability in normalized as well as the hot rolled condition.

Are you Looking to Purchase C45 /1045 Round, Flat Bars? Email Us – Get a Quick Quote!

Call Us for Best Prices for C45 /1045 Steel Bars, Forging’s – Immediate Deliveries Worldwide!

What is the Chemical Composition of C45 / 1045 Steel Bars?

| Chemical Composition % of Steel C45 (1.0503): EN 10277-2-2008 |

| Cr + Mo + Ni = max 0.63 |

| C |

Si |

Mn |

Ni |

P |

S |

Cr |

Mo |

| 0.43 – 0.5 |

max 0.4 |

0.5 – 0.8 |

max 0.4 |

max 0.045 |

max 0.045 |

max 0.4 |

max 0.1 |

| Standard |

Grade |

Chemical composition (%) |

| C |

Si |

Mn |

P |

S |

| GB |

45 |

0.42-0.50 |

0.17-0.37 |

0.50-0.80 |

≤0.035 |

≤0.035 |

| ASTM |

1045 |

0.43-0.50 |

0.10-0.20 |

0.60-0.90 |

≤0.040 |

≤0.050 |

| JIS |

S45C |

0.42-0.48 |

0.15-0.35 |

0.60-0.90 |

≤0.030 |

≤0.030 |

| DIN |

C45/1.0503 |

0.42-0.50 |

≤0.40 |

0.50-0.80 |

≤0.045 |

≤0.045 |

What are the Physical Properties of 1045 / C45 / S45C Carbon Steel Bars?

The Density of 1045 / C45 / S45C Carbon Steel is 7.87 g/cc.

What are the Mechanical Properties of 1045 / C45 / S45C Carbon Steel Bar?

| Mechanical Properties in Quenched+Tempered Condition |

| Diameter d (mm) |

Thickness t (mm) |

0.2 % proof stress (N/mm2) |

Tensile strength (N/mm2) |

Elongation A5 (%) |

Reduction Z (%) |

| <16 |

<8 |

min. 490 |

700-850 |

min. 14 |

min. 35 |

| <17-40 |

<8<=20 |

min. 430 |

650-800 |

min. 16 |

min. 40 |

| <41-100 |

<20<=60 |

min. 370 |

630-780 |

min. 17 |

min. 45 |

| Mechanical Properties in Normalized Condition |

| Diameter d (mm) |

Thickness t (mm) |

0.2 % proof stress (N/mm2) |

Tensile strength (N/mm2) |

Elongation A5(%) |

|

| <16 |

<16 |

min. 390 |

min. 620 |

min. 14 |

|

| <17-100 |

<16<=100 |

min. 305 |

min. 305 |

min. 16 |

|

| <101-250 |

<100<250 |

min. 275 |

min. 560 |

min. 16 |

|

Brinell hardness ranging between 170 and 210.

What is the Process for Forging of 1045 / C45 / S45C Carbon Steel Bars?

Hot forming temperature: 850-1200oC. Pre heat to 750 oC – 800 oC, then continue heating to 1100 oC – 1200 oC maximum, hold until temperature is uniform throughout the section and commence forging immediately. Forging is not workable below 850 oC. Finished forgings could be air cooled.

Other Designations for 1045 / C45 / S45C Carbon Steel Bar?

| EU |

USA |

Germany |

Japan |

France |

England |

Italy |

Spain |

China |

Sweden |

Poland |

Czechia |

Austria |

Russia |

Inter |

| EN |

– |

DIN,WNr |

JIS |

AFNOR |

BS |

UNI |

UNE |

GB |

SS |

PN |

CSN |

ONORM |

GOST |

ISO |

| C45 |

1042 |

C45 |

S45C |

AF65C45 |

070M46 |

1C45 |

C45k |

45 |

1650 |

45 |

12050 |

C45SW |

45 |

C45 |

| 1045 |

C45 |

50HS |

C45 |

| Gr.1043 |

|

|

|

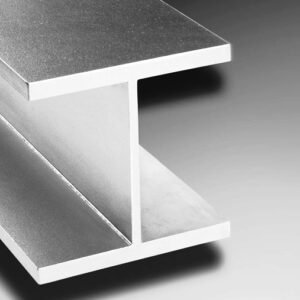

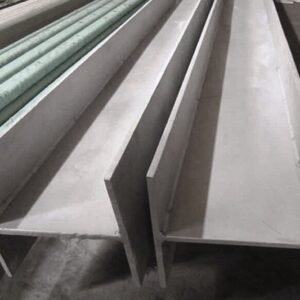

What are the Various Product Forms in which 1045 / C45 / S45C Carbon Steel is Produced and Sold?

- 1045 / C45 / S45C Carbon Steel Round Bars

- 1045 / C45 / S45C Carbon Steel Square Shape Steel or Flat Bars

- 1045 / C45 / S45C Carbon Steel Bar Steel Plate/Sheets

- 1045 / C45 / S45C Carbon Steel Forging’s

- 1045 / C45 / S45C Carbon Steel Hollow Bars and Pipes

Reviews

There are no reviews yet.